Inert Alumina Ceramic Ball for Catalyst Support Agent

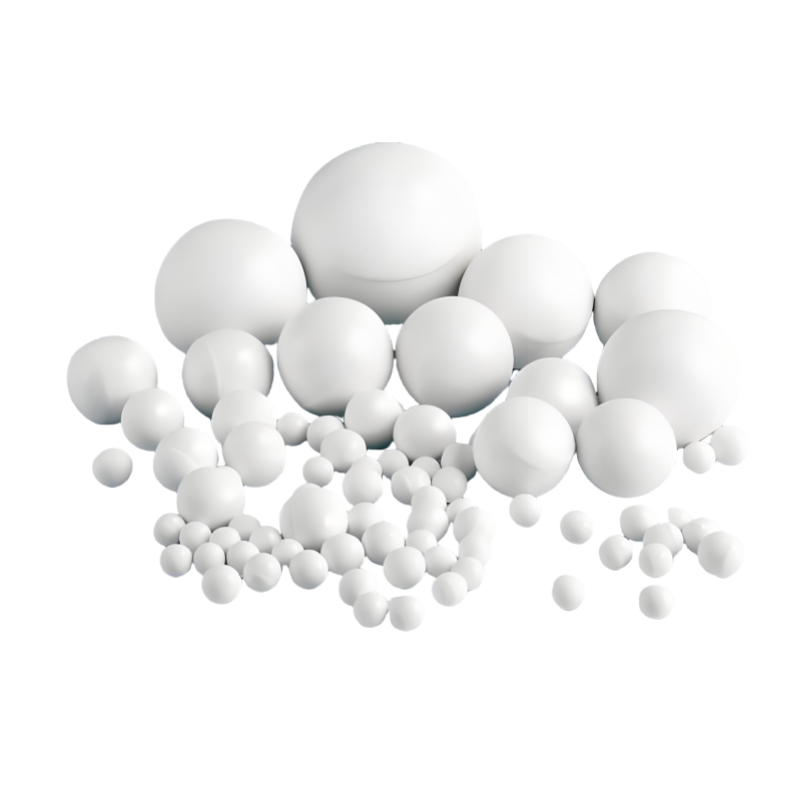

Ceramic Balls Introduction

Ceramic ball is a material widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries. The ceramic balls are used as the covering support material and column packing material for the catalyst in the reactor. It has the characteristics of high temperature and high pressure resistance, low water absorption and stable chemical properties.

It can withstand the corrosion of acids, alkalis and other organic solvents, and can withstand the temperature changes that occur during the production process. Its main function is to increase the distribution point of gas or liquid, support and protect active catalysts with low strength.

Classification of ceramic balls: Ceramic balls can be divided into two types according to their use: filling ceramic balls and grinding ceramic balls.

Ceramic Balls Picture

Ceramic Balls Technical Specification

|

Active Ceramic Ball Physical Properties |

||||||||||||

|

Specification,Φ |

3 |

6 |

8 |

10 |

13 |

16 |

20 |

25 |

30 |

38 |

50 |

75 |

|

Pore Volume, ml/g |

0.1~0.2 |

|||||||||||

|

Resistant to Sudden Temperature Changes, ℃ |

≥500 |

|||||||||||

|

Abrasion Rate, % |

≤5 |

|||||||||||

|

Crush Strength, N/Bead |

≥0.10 |

≥0.20 |

≥0.30 |

≥0.40 |

≥0.50 |

≥0.80 |

≥0.90 |

≥1.20 |

≥1.50 |

≥1.80 |

≥2.50 |

≥3.50 |

|

Bulk Density, kg/m3 |

1100~1300 |

|||||||||||

|

Note |

The bulk density is for reference only, not as acceptance data |

|||||||||||

|

Active Ceramic Ball Chemical Composition |

|||

|

Chemical Composition |

Ni-Mo Type |

Ni-W Type |

Co-Mo Type |

|

AI2O3 |

≥40 |

||

|

NiO |

0.5~1.0 |

0.5~1.0 |

|

|

CoO |

0.5~1.0 |

||

|

MoO3 |

1.5~2.5 |

1.5~2.5 |

|

|

WO3 |

1.5~2.5 |

||

Ceramic Balls Applications

- As a support and covering material for catalysts

- As an Ideal alternative to inert alumina ceramic ball